Summary

PMS’s inventory forecasting makes pharmacy operations intelligent and information-driven. It accurately analyzes previous sales, fluctuating demand and pharmaceutical trends and anticipates which medical stuff will be higher in demand in the current situation. Pharmacy software prevents stock-outs. Patients get medicine instantly without the need to wait at the counter for long hours. In this blog, I will discuss how inventory forecasting in PMS reduces overstock and expiry losses and improves cash flow. Also, I will cover how automatic alerts help in timely reordering and make the planning tangible. Let’s begin!!!

Introduction

Have you ever wondered how a minor stockout can turn into a significant loss? In today’s competitive world, keeping only medicine is not sufficient. Speed and availability build patient trust. Inventory forecasting in PMS is not an advanced version of stock tracking. It is a smart decision-making system that enables pharmacists to take a strategic approach throughout their journey. Traditionally, pharmacists depend on manual computations and prior experience to determine the patient demand. However, modern pharmacy management systems leverage live data and statistical modeling to anticipate the demand ahead of time.

Every medicine comprises some sales patterns; some are seasonal, some are daily fast-moving and few are emergency-based. Pharmacy management system analysis all the trends to determine the replenishment of medicines and their quantity. This prevents stock-out situations and empty shelves. It makes the pharmacy department’s reliability stronger. Plus, it minimizes overstock risks. Reduce expiry losses. Improves cash flow. And allow optimal use of storage space. Pms send automatic alerts when stock level goes down or demand spikes. To put it simply, PMS transforms hypothetical choices into analysis-based strategies where each medication is accessible at the appropriate time and in the appropriate amount.

The Stock-Out Crisis in Pharmacies

Supply Chain Disruptions

These days, pharmacies no longer just depend on local suppliers. Further, they are connected with a national and global supply chain as well. Delays in supplies negatively impact stock levels. 79% of pharmacy owners are facing operational headaches due to drug shortages.

When Shelves Become Empty

Stockout occurs when essential medicines are not available at the right moment. Additionally, patients wait in a long line, but disappointingly, the stock runs out at the end. Ultimately, patients get exhausted and lose faith in pharmacy services. Currently, Indian pharmacy centers are still confronting these challenges.

Pressure of Seasonal Demand

Few months face sudden spikes in specific medicines due to Flu season , dengue outbreak, or allergy time. Further, if pharmacists fail to make strategic plans in advance, they experience shortages in stock levels.

Local Effect of Global Issues

Indian pharmacy centers mostly face challenges with raw material scarcity, international transport holdups and manufacturing slowdowns. As per recent reports, 63% of operations are seriously impacted by global disruption.

Sales Loss or Customer Loss

Stockouts are not just about missed sales. They are the reason behind long-term loss. Further, customers move to the next pharmacy center if you are incapable of providing timely services. Pharmacies lose high revenue just because of availability gaps. Moreover, if the pharmacist still relies on the traditional approach for handling practices in 2026. You will lag behind your competitors. It’s the right time to upgrade your manual system with advanced hospital pharmacy management software.

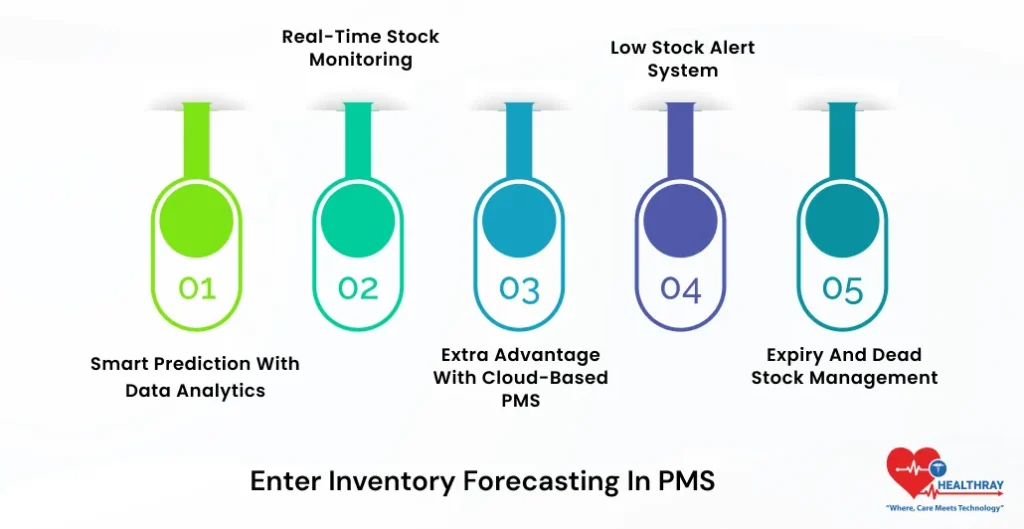

Enter Inventory Forecasting in PMS

Smart Prediction with Data Analytics

Modern PMSs are not merely limited to storing past sales records. Furthermore, pharmacy software utilizes statistical analytical techniques to deeply evaluate buying behaviors, seasonal fluctuations and patient preferences. It helps pharmacists determine which medicines are extremely prevalent. Also, pharmacists can predict which medicine demand goes up during flu season or outbreak time. They can dwell on reasons for slow-moving medicine. Additionally, these viable insights help make concrete decisions beforehand.

Real-Time Stock Monitoring

Real-time stock inventory is an incredible feature of pharmacy software solutions. Further, real-time stock analysis helps pharmacists understand current stock levels in the system. Here, every billing entry automatically adjusts the stock counts. Pharmacists no longer have to manually maintain stock levels, in contrast to traditional systems. It eliminates the need to repeatedly check medical quantity on every shelf. Moreover, pharmacy software instantly sends notifications when medicine quantity touches the predefined low level. Thus, pharmacists can reorder the stock at the right times. Patients experience less anxiety as a result of unforeseen stock-out circumstances.

Extra Advantage with Cloud-Based PMS

Cloud-based PMS such as Healthray is a groundbreaking platform for multi-branch pharmacies. Further, it synchronizes real-time data of all inventory stores. And highlights it in a centralized dashboard. It helps owners and managers to clearly view all the relevant data of stock in a single screen. Additionally, if any branch faces a stock crisis, the pharmacist can immediately transfer the medicine stock from another branch, if there is sufficient supply. Manager can accurately plan the system flow and take immediate actions in case of crisis.

Low Stock Alert System

Low stock alert system is an intelligent feature of pharmacy management software. Furthermore, it constantly tracks inventory resources present in the centers. It clearly defines the minimum stock level for every medicine. As the stock level quantity reaches below the predefined level, the system automatically sends an SMS, app notification and dashboard alert. This provides a clear signal to the pharmacist to reorder the stock. This feature eliminates the last-moment discomfort and optimizes the operation conveyance. Overall, timely alerts allow pharmacists to replenish the shelves in advance and avoid last-minute chaos at the counter.

Expiry and Dead Stock Management

Pharmacy management software can easily control expiry and dead stock. Further, pharmacy software tracks the expiry date of every batch. As the medicine begins to close, pharmacy software starts sending notifications. PMS clearly indicates medications that move too slowly or do not move at all. This smart visibility prevents unnecessary wastage of medical stuff. In the traditional system, pharmacists require huge efforts to collect data of slow-moving or expired medicine. Automation prevents money from becoming stuck in an expired system. Allows better management of working capital. Overall, automation creates a seamless environment and refills the shelves at the right moment.

Core Forecasting Techniques in PMS

Time-Series Analysis for Demand Trends

Modern pharmacy software is built on time-series models, such as ARIMA and Prophet. Further, these models can read past data and based on that, they can anticipate future predictions. It can seamlessly analyze seasonal variations, weekly patterns and long-term development. System provide clear visibity on vaccine demand during flu seasons. Also, it can forecast probable demand for chronic medication to help pharmacists to plan the stock prior to arrival.

Regression Models for Real-World Factors

Relying only on past data is not sufficient. Furthermore, pharmacy software is efficiently trained on machine learning regression models. It analyzes all the external factors that impact the practices. Pharmacists can easily determine how weather variations, celebrations, local epidemics and lifestyle patterns shape the sales growth. Additionally, the PMS in healthcare adjusts the reorder level based on the above circumstances. In simple words, pms meticulously scrutinizes the real-life situations and organizes the stock according to that.

EOQ Integration for Cost Control

Economic Order Quantity (EOQ) assists PMS to calculate stock levels that can give highly profitable results. This helps pharmacists maintain balance with maintaining expenditures, ordering frequency and deadline risk. Additionally, when you integrate forecasting with pms software, the likelihood of risk is minimal, especially in the case of perishable products and short-duration pharmaceuticals.

PMS Features for Proactive Stock-Out Prevention

Real-Time Inventory Tracking

Modern PMS applies barcode POS and RFID technology to maintain a live count for every medicine. Furthermore, pharmacy software updates all the stock levels once it gets sold out. Unlike traditional systems, pharmacists no longer need to update every stock level as it proceeds to sell. Whether it’s a single store or a multi-chain center, the system automatically updates the stock level. Therefore, it blocks the formation of data silos in different locations. It minimizes the chances of unexpected storage that creates uncertainties in the ongoing operations.

Automated Replenishment System

PMS suggests automatic reordering of stocks once it crosses the predefined threshold level. Thus, it minimizes last-minute headaches of reordering stuff. It evades the need to check each inventory from different data sets and files. All details are displayed in single dashboards. Furthermore, as the stock level quantity goes down, the system automatically connects it with the supplier and initiates a replenishment of the pharmaceutical stuff. Pharmacy software also suggests smart alternatives if the product is unavailable.

Demand Simulation for Risk Planning

Advanced PMS assesses demand fluctuation. Furthermore, pharmacy software runs multiple times “what-if” scenarios to deeply understand the unpredictable outbreak, supply delay, and demand spike circumstances. This helps the pharmacist adeptly establish the safety stock level. Thereby, helping pharmacists to easily adapt to the situations beforehand. They can safely take the actions before the crisis takes place.

Batch Tracking for Complete Control

Pharmacy software is adept at tracking the batch number, manufacturing date and expiry date of every medicine. Furthermore, this aids the pharmacy division in conveniently handling the recall situation. This minimizes the risk of monetary wastage on expired pharmaceutical assets. Overall, it helps pharmacy centres take tangible actions before the situation turns worse and prevents wastage on purchasing unnecessary resources.

Conclusion

Inventory forecasting PMS allows pharmacists to transform their practices from manual valuation to smart, statistically informed strategy. With pharmacy management software, all decisions are based on real demands. Smart forecasting minimizes the slow-moving stock and expiry risks. Platforms like Healthray optimize the workflows, boost efficacy and are adept at handling sudden demand shifts.